- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

Beneficiation Plants and Pelletizing Plants for Utilizing ...

1. Iron ore supply and demand outline Types of iron ore Iron ores can be classified in different ways. The most important has to do with the iron content. In many cases, ore with a total iron content of 60% to 63%, or greater, is regarded as high grade, and ore with a lower iron .

The Economic Reality of Iron Ore Production amid ...

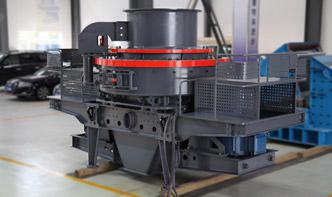

grinding, separation, tailing, ... The use of gyratory crushers utilized in reducing or crushing hard iron ore body, before it is transformed into its finished state (iron ore concentrate). In addition, the company is made up four departments, namely, beneficiation, mines, administrative and estate departments.

CATALOGO CHROMITE PDF

· And the chrome beneficiation machines are also. Cari Death Crusher Rohan – topsecon. Menu Project case Basalt stone processing plant Carbon grinding plant Dolomite stone processing plant Feldspar stone processing plant Iron ore beneficiation plant Kaolin processing plant Limestone Processing Plant Sand Making Plant Talc processing plant.

EFFECT OF SIZE DISTRIBUTION AND WATER CONTENT ON ...

Grinding of iron ore to required uniform size Concentration of iron ore and separation of unwanted gangue material Addition of binders, additives, etc. for preparation of agglomeration mixture 2. Green Ball Formation: In this step, the pellets are rolled by addition of moisture.

The Six Main Steps of Iron Ore Processing | Multotec Canada

· This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground. Once the ore has been crushed, it is diverted to a stockpile. The aim of this step is to ensure a smooth crushing process and minimize downtime in the event of a breakdown or to allow planned maintenance in the crushing system, without stopping the grinding and other further steps.

Overview of the steel and iron ore market 2020

Key Findings Overview of the global steel and iron ore market • In 2020, global steel production is expected to decrease by percent YoY, to 1,799 million tonnes. • China's output will continue to grow in 2020 (by 4 percent YoY) due to initiatives aimed

Industrial Solutions polycom highpressure grinding roll

Declining ore grades, fine grade ores and the environmentally sustainable use of water are major challenges facing not just the iron ore industry but, increasingly, the entire mining industry as well. It needs energyefficient grinding circuits to offset increasing costs. The polycom ® dry finish grinding concept in combination

Different Types of Iron Ore

· Iron formation consists of iron ore such as siderite, magnetite, and hematite, with silica in the form of chert, jasper, etc., generally in bands, but sometimes not distinctly so. The bands of iron ore are at times highgrade, but are often mixed with a good deal of silica, the whole making an ore too lean for use without concentration.

Outotec to supply Planet Positive grinding ...

· Our stirred milling technology with its excellent performance and ability to increase both iron ore concentrate and recovery has proven itself multiple times in the Chinese market. The new installation will also benefit from classleading energy efficiency and wear life," says Christoph Hoetzel, Head of Grinding business line at Outotec.

Metallurgical Testing for Iron Ore

semiautogenous grinding (SAG) and metallurgical pilot plants on iron ores, including extremely large plants treating up to 1,000 tonnes of ore and lasting for 6 months. Many complex circuits using autogenous grinding, desliming, magnetic separation, gravity separation, selective flocculation, and flotation have been run in our laboratories.

Iron Ore Technical Centre

The ALS Iron Ore Technical Centre has been designed and built to accommodate scalable fused bead XRF processing capacity in excess of 10,000 samples per day. With specialist expertise in processing hematite, magnetite and all forms of iron ore, the centre provides extensive ore characterisation,

The Latest Developments in Iron Ore Processing

The Latest Developments in Iron Ore Processing ... –Fine grinding, pellitisation Flotation. Typical Magnetite Processing Circuit Crushing HPGR "212" micron Coarse LIMS max 5 passes Fine LIMS max 5 passes Fine TBS "75" micron 1 5 4 3 2 7 6. LIMS Plant. Wet Low Intensity Magnetic Separator (LIMS)

Iron Ore

Expertise in iron ore processing Our teams have distinctive capabilities in iron ore technology across the full range of recovery techniques and unit processes, from ore beneficiation through to final product. We address the needs of projects large and small, and provide services from early stage studies through to full project implementation.

Industrial Grinding Estimation of Blended Ore from ...

Industrial Grinding Estimation of Blended Ore from Porphyry Copper Deposit Irena Grigorova1, Marin Ranchev2, Teodora Yankova3, Ivan Nishkov4* 1Associate Professor DSc, University of Mining and Geology "St. Ivan Rilski", Department of Mineral Processing and Recycling, Sofia, Bulgaria.

Relationships between comminution J energy and product ...

bulk ore. It was found that grinding properties differ significantly and therefore separate grinding test work may be required for each grinding step in the magnetite ore beneficiation flowsheet. Keywords: grinding, iron ores, particle size, modelling. * Process Technology and Innovation. † Hacettepe University, Turkey. ‡ Deloitte ...

Copyright © .CMichineAll rights reserved.خريطة الموقع