- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Cement Equipment In Cement Plant | AGICO Cement Plant ...

Cement Equipment Supplier. AGICO GROUP is loed in Henan, China. Our company was founded in 1997, with the registered capital of million RMB. It covers an area of 660000m 2 and has a construction area of 30000 m 2. In 2004, we passed the ISO9001 certifiion and enjoyed the selfmanagement right of import and export.

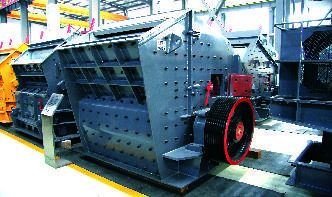

Mining Ball Mill online Wholesaler miningballmill

Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill. High efficiency rock river stone impact crusher pf1010 for sale. Contact Supplier. High Efficiency Stone Crusher Double Rotor Pf 1010 Series Impact Crusher. Contact Supplier. Ball Mill In Cement Plant 1200*2400 Mine Ball Grinding Mill Price.

Hydraulic Roller Press

Compared to the pregrinding systems including ball mills with high energy consumption and low efficiency, these cement mill roller presses consume less energy and produce lower noise. This roller press can improve the grinding capacity by 50 compared to ball mill systems and reduce the power consumption of the grinding system by 3040% ...

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energyefficiency. Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range. Whether grinding raw coal, clinker, cement and/or slag, we ...

Ball mill

The Description and Function of Ball Mill: Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silie product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry.

efficiency ball mill, efficiency ball mill Suppliers and ...

4,572 efficiency ball mill products are offered for sale by suppliers on, of which mine mill accounts for 26%, grinding equipment accounts for 4%, and flour mill accounts for 1%. A wide variety of efficiency ball mill options are available to you, such as years, 3 years, and more than 5 years.

Ball Mill Steel Ball Size Chart Coal Ruassia

High Efficiency Grinding Machinery Ball Mill Cement Mill. Impact Ball Mill With High Efficiency For Sale. Ball charge and grinding efficiency amp classifiion circuits what is important for efficiency is the loion of the energy spectra high impacts vs low impact for ball mills low impact is more important because of the smaller particles ball mill liner efficiency based ...

ball mill relining standard operating procedure pdf free

which company high efficieny cement ball mills; small ball mill specifiion pdf; micro ball mill for sale; ball mechine for cement grinding manufacturer in india; crushing fabricacion ball mill; calculation of ball mill critical speed; ball crushing for gold mine south africa; biggest ball mill in africa; ball mill .

Energy Saving Ball Mill|Cone Ball Mill|Tube Ball Mill ...

In Gongyi Hongrun, we provide ball mills of many kinds such as energy saving ball mill, cone ball mill, tube ball mill, cement mill, steel slag mill, etc. ... [01/06/2016] High Efficiency Ore Grinding Ball Mill [12/29/2015] The Basic Principle of Steel Ball Selection of Ball Mill

Ball Mills

For many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice. In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ...

Cement Grinding Stage

In raw grinding, a ball mill with a high efficiency separator is used to achieve uniform particle size in raw mix for the next stages of the manufacturing process. At the Cement Grinding Stage, 90 – 95% of the clinker is mixed with gypsum and ground in a Cement Ball Mill to .

which company high efficieny cement ball mills

cement mill ball calculation ... cement processing plant, cement grinding machine,ball . which company high efficieny cement ball mills . vertical raw mill cement ..... Mining Ball Mill, Mine Ball Mill, Cement Ball Mill. Ball Mill From China Zenith. ... cement and chemical industries. With high comminution ratio,it can carry out dry or wet ...

Vijay Cements – Vijay Cements Company

The Clinker, Flyash and Gypsum are fed to the cement mills through electronic weigh feeders at controlled rate and ground in ball mills The classifier (high efficiency separator) controls the fineness of cement. The finished product of desired chemical composition and physical properties is transported to Cement Silos for storage.

Fives | Grinding solutions for cement and minerals ...

Grinding in ball mills with FCB Bmill. Fives' FCB Bmill® goes beyond the traditional ball mill, which is used for grinding raw materials, cement, solid fuels and minerals. The FCB Bmill can grind products at high fineness and can adapt to very abrasive and moist products.

BALL MILL MAINTENANCE COURSE

The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system. This course offers an indepth understanding of the maintenance activities, providing the precise tools to achieve optimal levels of personal performance and ...

Ball Mill Design/Power Calculation

Jun 19, 2015 · The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ...

Best energy consumption

Feb 16, 2015 · The ball mill has been the industry's workhorse for over a century and despite its estimated meagre four per cent efficiency, little has changed over the years other than increases in the wear resistance of mill internals and the scale of the equipment.

Copyright © .CMichineAll rights reserved.خريطة الموقع