- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

SM 300 Cutting Mill | Glen Mills, Inc.

SM 300 Cutting Mill. Cutting mills are suitable for the grinding of soft, mediumhard, tough, elastic, fibrous, and heterogeneous mixes of products. The new Cutting Mill SM 300 excels especially in the tough jobs where other cutting mills fail. The high torque of the new 3 kW drive with RES technology (additional flywheel mass) allows for an ...

(PDF) Grinding in Ball Mills: Modeling and Process Control

· Grinding in Ball Mills: M odeling and Process Control Vladimir Monov, Blagoy Sokolov, Stefan Stoenchev Institute of Information and Communiion Technologies, 1113 Sofia

Grinding Milling | Glen Mills, Inc.

Thanks to its robust design, the Disc Mill DM 400 can be used under rough conditions in laboratories and pilot plants, as well as online for the quality control of raw materials. The powerful DM 400 requires only a few minutes to achieve the desired grind size. SKU: n/a. Add to Wishlist. Compare. Ball Mills, Grinding Milling.

Variable Speed Rotor Mill PULVERISETTE 14 premium line ...

Fast pre and finegrinding in one instrument . The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 premium line offers impact, shearing and cutting comminution in one instrument – with a higher performance, better cooling and is significantly quieter than comparable instruments. Its powerful motor is ideal for the particularly fast comminution of soft to mediumhard, brittle as well as ...

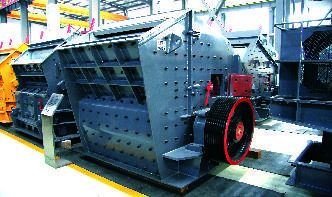

Hammermill Crushers | McLanahan

The Standard and NonClog Industrial Hammermills are designed to reduce the material to a nominal 3" to 5" (75mm to 25mm) output. These are primary stage crushers, commonly followed with Centerfeed Mills or other types of secondary stage crushers. The HammerMaster is also a secondary stage crusher in that the maximum feed size is 6" (150mm).

Impact Dryer Mills | Drying Grinding ...

Impact Dryer Mill Appliions. Williams Impact Dryer Mills are often referred to as Crusher Dryers or Dryer Mills. Our proven technology is integrated into a complete system for the simultaneous grinding, drying, and classifying of materials, and conveys the product in one continuous, automated operation. Some of the many appliions for our crusher dryer systems include:

BASIC CEMENT PLANT LAYOUT – Process Cement Forum – The ...

· Jaw crusher is basically a simple mechanism having two plates one fixed and another moving. This is also called primary crusher. Hammer crusher has got metallic hammer mounted on the axes and the sizing achieved by the impact of the hammer. 13 Coal Mill Building . The coal mill building houses the mill for grinding lumpy coals.

HGM80 Ultra Fine Grinder millgrinding mill/ultrafine mill ...

HGM80 Ultra Fine Grinder mill is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness under six. Such as calcite (calcite carbonate, calcium carbonate), chalk, limestone, dolomite, kaolin, gypsum, etc, totally more than 100 kinds of materials. Product fineness can be controlled between and

Vertical Roller Mill,Vertical Roller Mill Operation

Two Types of vertical roller mill. New type vertical roller mill is SBM to solve the industrial grinding mill low yield, energy consumption higher technical difficulties, absorbing advanced technologies from Europe and combination of SBM grinding milling machine many years design advanced manufacturing concept and the needs of the market, after years of painstaking the improved design of ...

Products

Raymond Mill. Raymond mill has a history of over 100 years. So, it's classic undoubtedly. Recent years, with the growth of nonmetallic mineral grinding industry, ZENITH upgraded Raymond mill to make it have more appliion areas, and, meanwhile, own high degree of reliability and automation.

Home

Gold Grind Machine Description: Gold grind machine will cooperate with materials and water to join in mixed, when they mix, the process will have a functions of stirring and squeezing, cone wet grinding machine can remove the air between materials, even stir, .

Description

IKA MultiDrive control. Regardless of whether samples are hard, soft or fibrous – the IKA MultiDrive crusher can perform a wide range of crushing tasks involving coarse and fine crushing, thanks to the variety of vessels available. MultiDrive control mixes, grinds and is also fitted with a dispersion vessel and a disposable tube.

Distillery Milling Efficiency | Stedman Machine Company

Distillery milling breaks up cereal grains so that water can penetrate and facilitate the cooking process. Grinding increases a grain's surface area. More surface area gives water and enzymes a better opportunity to penetrate the grain. A particle 1 inch in diameter has .

Crushers, Grinding Mill, Mobile Crusher Machine For Quarry ...

HGT Hydraulic Gyratory Crusher. HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together. And the automatic control system, its the greatest feature, makes operation more convenient. Gyratory Crusher

Industrial Roller Mill | Roller Mill ...

Roller mills are industrial mills that uses cylindrical rollers to crush and grind material instead of flat plates like other pulverizers. The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance.

Ball Mills | Industry Grinder for Mineral Processing ...

Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel balls, or ceramic are used in the collision container. The ball milling process is prepared by rod mill, sag mill (autogenous / semiautogenous grinding mill), jaw crusher, cone crusher, ...

How it Works: Crushers, Grinding Mills and Pulverizers ...

· Grinding Mills and Pulverizers. Grinding mills and pulverizers are the second level of material reduction equipment after crushers. Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it. As there is with crushers, there are many different types of grinding mills and pulverizers available.

Grinding Crushing Mill

VIBRADRUM® Grinding Mills excel over conventional ball, stirred media, or vertical roller mills in both grinding and energy efficiency. The features listed below highlight why our mills are so effective and efficient. Proven energy savings range from 35 to 50% reductions in kW hours per ton of .

Crushing Vs Grinding

Crushing is usually a dry process, while milling is performed with water. The advantage of wet milling is the lower energy input compared to dry milling. Additionally, some chemical reagents can be used to minimize the energy consumption of grinding, because grinding energy is minimum at pH of the point of zero electrical charges of the ...

Jaw Crushers | Glen Mills, Inc.

Home Grinding Milling Jaw Crushers. Jaw Crushers. Showing all 7 results. ... Control of the gap width and zero point adjustment allow for reproducible results. ... To avoid metallic contamination, the grinding chamber of the jaw crusher is available of ceramic materials.

Crushers, Mills Grinders

Crushers, Mills and Grinders from the EngNet Engineering Directory and search engine. Find suppliers, manufacturers and distributors for Crushers, Mills and Grinders including Jaw Crushers, Cone Crushers, Ball Mills, Hammer Mills.

Hammer Mill Noise Control | eNoise Control

Hammer Mill Noise Control. Hammer Mills work on the principle that most materials will crush or pulverize upon impact using a three step operation. This operation can be very noisy and loud. eNoise Control provides noise control solutions appropriate for hammer mills. Material is fed into the mill's chamber typically by gravity.

Raymond Mill – Stone Crushers Grinding Mills for Mines ...

Learn More About ® Raymond Mill. 1. The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system. 2. Compared with other milling plants, its passing ratio achieves 99%, this is what other mill can not reach. 3.

Crushing Grinding

As ore is crushed into small pieces in the crushing and grinding mill area, mechanical failures are inevitable for primary, secondary, and tertiary crushers. Our solutions can enable you to maximize availability, extend the lifetime of mechanical equipment, and reduce costs by detecting emerging problems on crushing equipment before they occur.

Copyright © .CMichineAll rights reserved.خريطة الموقع