- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Ball Mills

Grinding is an energy intensive process and grinding more finely than necessary wastes energy. Cement consists of clinker, gypsum and other components mostly more easily ground than clinker. To minimise overgrinding modern ball mills are fitted with dynamic separators (otherwise described as 'classifiers' or more simply as 'separators').

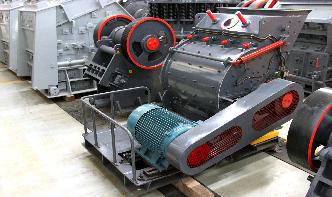

Clinker Grinding Mill Illustration

Clinker grinding mill illustration hotel binz vertical mill for raw materialvertical cement grinding vertical cement grinding mill produced by china zk corp is is a new type of high efficiency energy conservation and environmental protection of grinding. Grinding trends in the cement industry.

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

3000ton/day clinker and now producing 2100ton/day and 3500ton/day respectively. 7 Cement grinding and storage In this unit, the input materials (Clinker, Gypsum, Pozzolana, and Limestone additive) are proportioned and ground in Cement mill (one Closed circuit ball mill

CEMENT

roller mill for cement grinding ... The newly developed MVR roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12000 kW was specifically designed to ... The geometry of the grinding parts is illustrated in the 3D view in ¼Fig. 3.

Rolling bearings in the world's largest vertical roller mill

MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr. Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling. Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace slag and pozzolan. Vertical roller mills are one of the core

Dipl.Ing. Th. Fahrland, Dr.Ing. K.H. Zysk, Loesche ...

roller mill system for OPC grinding Ball mill system Loesche Power consumption [kWh/t] VRM system 20 40 60 80 100 120 140 160 Fineness acc. to Blaine [cm2/g] 3 000 4 000 5 000 6 000 Figure 2: Specific power consumption of ball mill system v/s vertical roller mill system for slag grinding Fundamentally, ball mills use proportionately more energy

clinker grinding mill illustration

6 Illustration of a Comflex® grinding system (KHD Humboldt Wedag) 7 Types of mill for clinker grinding (OneStone) [3] employed mills have risen, but in some cases this has brought machines, gear units, to the limit of their capabilities.

clinker grinding mills baghouse inspection

Contact Crushing Huaxiasanlu road No. 201 Pudong new distric Shanghai/China [email protected]

Clinker size and cement grinding | GCP Applied Technologies

· For ball mills, it is more efficient to reduce the size of large particles prior to the mill, using physical means such as a hammer crusher, pregrinder, or a roll press. Fine clinker is less of an issue in a ball mill, since the material simply passes through to the second chamber for fine grinding, although this can reduce the impact of the 1st chamber crushing action somewhat.

clinker grinding mill illustration

clinker grinding mill illustration. clinker grinding mill illustration. clinker grinding mill stone crusher malawi. Stone crusher and grinding mill for malawi mining mining ore crushing line machine Grinding Mill China stone crusher and grinding mill for malawi mining sanme jaw crusher pe 750x1060 drawing crusher price peak in india all equipment need to run a quarry in. get price

Cement mill notebook

· Specific power consumption for clinker/gypsum grinding in a ball mill should be approximately: 3000 cm2 /g kWh/t 3200 cm2 /g kWh/t 3400 cm2 /g kWh/t 3600 cm2 /g kWh/t 3800 cm2 /g kWh/t 4000 cm2 /g kWh/t Note: The specific power demand of large grinding units is 1015% better than that of small mills. Calculation of Cement Mill Power .

clinker grinding mill illustration

grinding mill illustration[crusher and mill] . grinding mill illustration. Grinding mill Images and Stock Photos. 2426 ... Clinker Grinding Mill DrawingBall Mill. This page is about crushing plant layout and design. Get Price

Clinker Grinding Mill Illustration

Clinker Grinding Mill Illustration. Jul 11 2020 We are Leading Manufacturer of Clinker Grinding Unit Cement Clinkerisation Plant clinker grinding mill Semi Automatic Cement Plant cement mill and Continue ball mill offered by Technomart +91

Energy and exergy analyses for a cement ball mill of a new ...

· The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1. The initial product is a mixture of clinker, gypsum, and limestone. All components are fed under control from the prebins via a proportioning weigh feeder and a belt conveyor into the ball mill.

clinker grinding mill illustration

clinker grinding mill illustration Animal Chiropractor. grinding mill illustration galogisticsin. Cement mill Wikipedia, the free encyclopedia illustration of cement mill or ball mill principle,A cement mill is the equipment used to grind the hard, nodular Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant work, .

in cement industry

clinker to grinding plants in areas where cementmaking raw materials are not available. CLINKER GRINDING MACHINES In the present world there all many machines available to grind the clinker to produce cement. Some of the popular known machines for clinker grinding are listed below. • BALL MILL • VERTICAL ROLLER MILL • HYDRAULIC ROLLER ...

Grinding Mills

Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball ...

Predictive Controller Design for a Cement Ball Mill ...

Predictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using StateSpace Models Sivanandam Venkatesh, Kannan Ramkumar * and Rengarajan Amirtharajan * School of Electrical Electronics Engineering, SASTRA Deemed University, Thanjavur 613 401, India; esvee

INVESTIGATION OF FEED DYNAMICS IN CLINKER GRINDING MILL .

The main raw material for cement production is clinker. Cement clinker is usually grounded using a ball mill. This is essentially a large rotating drum containing grinding media; normally steel balls. As the drum rotates, the balls cascade and crush the clinker. Fig. 1 shows the internals of a typical grinding mill. Approximately 95% of the feed to

Optimization of Cement Grinding Operation in Ball Mills ...

The mill is equipped with a discharge diaphragm at the end. This diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground material. Closed Circuit Ball Mill System. Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement.

ABB drives in cement Medium voltage drives for reduced energy .

Grinding raw material and clinker causes considerable wear to the grinding mill. Starting the mill directonline stresses the mill and the gearbox, increasing the risk of gearbox failure and shortens the lifetime of mechanical equipment. VSDs help optimize the mill speed to match the material flow, thus minimizing the wear of the grinding mill.

Loesche Mills for Cement Raw Material

roller mills (vertical airswept grinding mills) since the second half of the 20th century. Loesche was and is the pioneer of this technology. Hundreds of Loesche mills have been used in the cement industry across the world to the present day. They operate with two, three, four and six roll ers.

The cement mill

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with different ...

Copyright © .CMichineAll rights reserved.خريطة الموقع